0102030405

Manual Gear Operator For Quarter-Turn Valve

Product Features

● Torque range:260N.m to 58000Nm.

● Conforming to ASTM ISO5211, ISO5210, and JB2920 standard.

● High transmission efficiency.

● Superior protection against dust and water.

● Manual and pipe network application.

● 90° rotation (±5°).

● Stable self-locking performance.

● Weather proof level : IP67 (option: IP68).

Product specifications

Model |

Speed ratio |

Input torque |

Output torque |

Flange Size |

Maximum stem diameter |

Maximum install height |

Handwheel diameter |

JMG15 |

27 |

32 |

260 |

(F05)F07 |

20 |

55 |

200 |

JMG20 |

37 |

47 |

520 |

F07/F10 |

28 |

58 |

200 |

JMG21 |

38 |

75 |

850 |

F10/F12/F14 |

36 |

63 |

300 |

JMG30 |

40 |

113 |

1350 |

F12/F14/F16 |

48 |

85 |

350 |

JMG55 |

47 |

142 |

2000 |

(F12)/F14/F16 |

53 |

90 |

350 |

JMG58 |

55 |

152 |

2500 |

F16/F20 |

62 |

95 |

400 |

JMG88 |

61 |

164 |

3000 |

(F14)/F16/F20/F25 |

65 |

105 |

500 |

Advantage

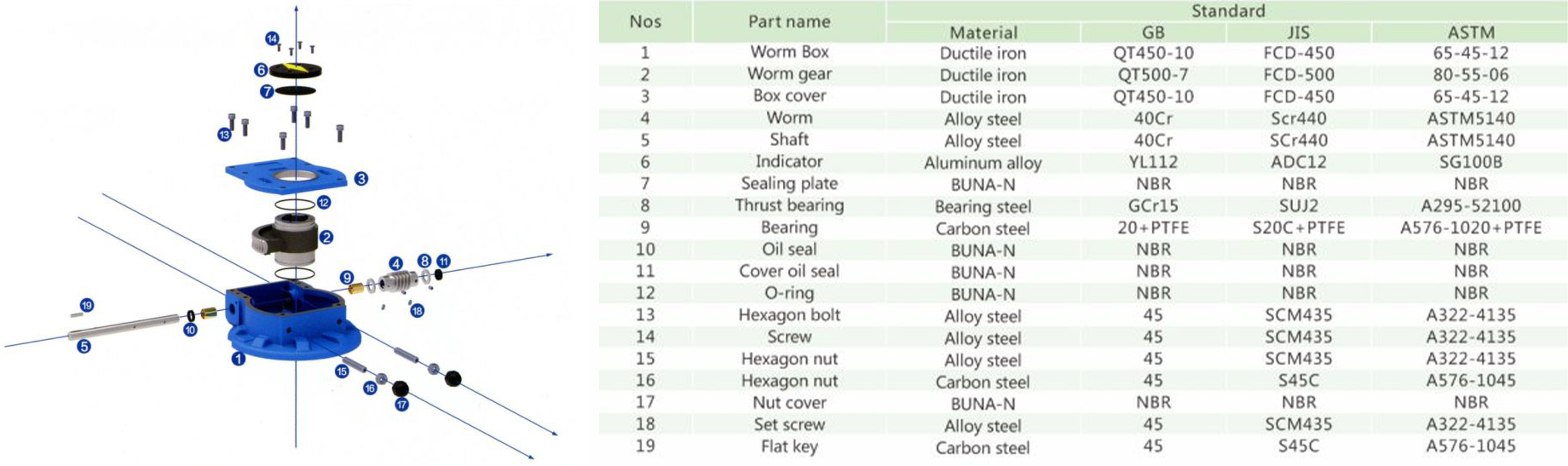

Explored View and Material

Technical parameter

| JMG Manual series technical parameter | ||||||||

| Mode | Speed atio |

Input torgue |

Output torque |

Amplitude factor |

Connection flange |

Max.Valve steam Diam |

Max.Install Height |

Handwheel Diam |

| JMG15 | 27 | 32 | 260 | 8.1 | (F05)F07/F10 | 20 | 55 | 200 |

| JMG20 | 37 | 47 | 520 | 11.1 | F10/F12 | 28 | 58 | 250 |

| JMG21 | 38 | 75 | 850 | 11.3 | F12/F14 | 36 | 63 | 300 |

| JMG30 | 40 | 113 | 1350 | 11.9 | F12/F14/F16 | 48 | 85 | 350 |

| JMG55 | 47 | 142 | 2000 | 14.1 | F14/F16 | 53 | 90 | 400 |

| JMG58 | 55 | 152 | 2500 | 16.4 | F16/F20 | 62 | 95 | 500 |

| JMG88 | 61 | 164 | 3000 | 18.3 | F16/F20/F25 | 65 | 105 | 500 |

| JMG88-S32 | 167 | 90 | 4200 | 46.7 | F16/F20/F25 | 65 | 105 | 500 |

| JMG100-S32 | 177 | 111 | 5500 | 49.5 | F20/F25 | 72 | 110 | 500 |

| JMG195-S32 | 167 | 139 | 6500 | 46.8 | F16/F20/F25 | 80 | 115 | 600 |

| JMG195-S40 | 208 | 129 | 7500 | 58.1 | F16/F20/F25 | 80 | 115 | 600 |

| JMG300-S50 | 290 | 117 | 9500 | 81.2 | F25/F30 | 95 | 145 | 600 |

| JMG300-DS60 | 348 | 117 | 11000 | 94.0 | F25/F30 | 95 | 145 | 600 |

| JMG680-DS60 | 372 | 139 | 14000 | 100.7 | (F25)F30/F35 | 115 | 148 | 600 |

| JMG680-DS80 | 519 | 121 | 17000 | 140.5 | (F25)F30/F35 | 115 | 148 | 600 |

| JMG780-DS100 | 587 | 145 | 23000 | 158.6 | F30/F35 | 125 | 157 | 600 |

| JMG980-DS120 | 756 | 147 | 30000 | 204.1 | (F30)F35 | 140 | 180 | 600 |

| JMG1080-DS150 | 005 | 147 | 40000 | 272.1 | (F30)F35/F40 | 150 | 195 | 600 |

| JMG1180-DS200 | 1467 | 116 | 46000 | 396.6 | (F35)F40 | 160 | 230 | 600 |

| JMG1280-DS300 | 1618 | 133 | 58000 | 436.1 | (F35)F40 | 170 | 230 | 600 |